“Coconut”: Raw Materials and Pre-Processing

This article is a supplement to our “Secret of Coconut” article, which describes various ways modern hobbyists have attempted to reproduce a certain kind of fuzzy-looking coating on vintage cardboard Christmas “putz” houses.

Because the appearance reminded collectors of coconut, they used that term to describe both the houses that used it and the material itself.

Most hobbyists believe that most of the Japanese putz house builders used rice straw, which is so cheap in rice-producing countries as to be all but free. Unfortunately, it’s hard to get rice straw for anything like a reasonable price in most of North America. Several hobbyists who’ve contributed the discussion are pleased with the results they get from wheat straw. However they come by it in different ways, and how you get the material affects your how you have to “work” it to get it ready for chopping.

Note: These articles are based on notes from a number of putz house builders and restorers who’ve attempted to replicate the original finish to use on their own construction. We’re publishing them because the questions keep coming in. But we did want to point out that none of the people who contributed to the article (including me) have any intention whatsoever to make this stuff to sell commercially - there are a lot of easier ways to make a living, and there’s already a fellow - Pete Oehman, who makes a better product than I ever will. We’ve done our best to give you the information you need to “roll your own,” but if you’d rather finish that structure than learn a new skill, or if you need to match a difficult color, contact Pete through CardboardPutzHouses.com and tell him we sent you.

By the Bale

One reader gets by the bale at his local feed mill or area farms.

Processing: This reader pulls out straws and cuts away the knobby joints, then uses scissors to cut the individual straws into 1” or shorter lengths, which he then uses a blender to chop.

In Craft-Store Wreath Forms

Another reader buys those straw wreath forms from craft stores. This has the advantage of being pre-processed and cleaned to a certain degree. In fact, considering where some of these are made, it’s entirely possible that you are buying rice straw when you buy these.

Preprocessing: This reader uses a sharp handsaw (like the Stanley “Sharptooth”) to make one cut, then straightens the material out into a log shape and makes “rough cuts” in a wooden jig. No, we’re not saying you have to build one of these, only that it can be done. If you want to try a simpler method first, or you find some other way to preprocess your source material, nobody will be mad at you. We only ask that you share the method that works for you.

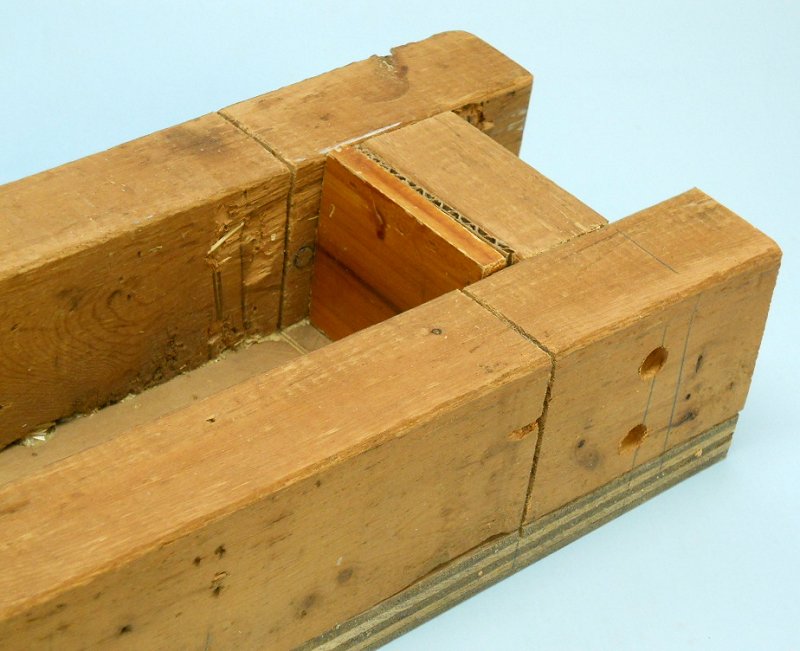

The jig is a wooden channel like a miter box with an adjustable stop at one end. Here are a couple of photos to give you an idea of how it went together.

The base is 6" x 12" x 3/4".

Each side is cut from 2”x3” stock. Measurements are 2 1/2" x 1 1/2" x 12".

The stop is also cut from 2”x3” stock. Measurements are 3" x 2 1/2" x 1 1/2 ".

Your measurements will vary depending on the diameter of the wreath stock you plan to use.

The “shims” are little rectangles that slide in front of the stop to let you adjust the length of your cuts - That way if you discover that 1/2” lengths will work better in your bender than 1” lengths, you don’t have to rebuild the jig.

The “kerf” (slot for the saw blade) is eight inches from the end the straw goes in.

You can fasten the whole thing together with a few screws and some wood glue.

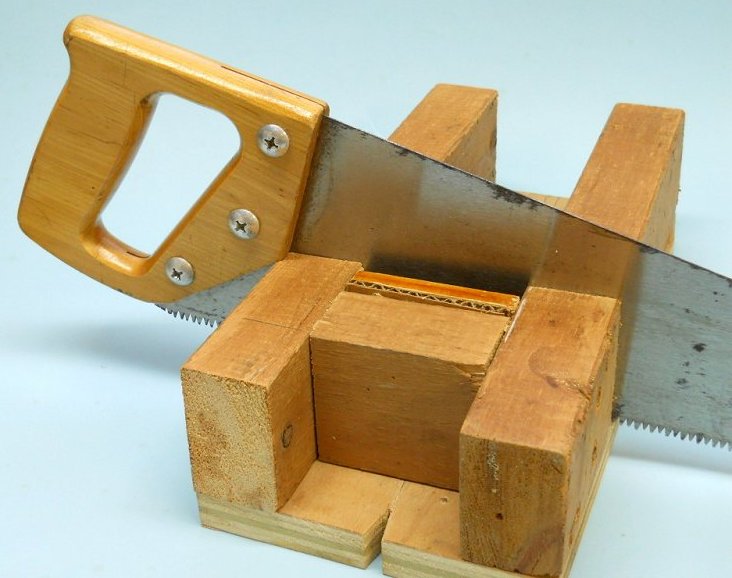

The photo to the left shows how the saw goes into the kerf. The photo to the left shows how the saw goes into the kerf.

If you didn’t buy a very sharp saw for this, it will take you a lot longer and your shoulder will be a lot sorer at the end of the process.

To use, push the straw “log” up against the “stop” and cut.

This process makes a lot of “rough-cut” straw.

It also makes a very big  mess, so be sure and work somewhere that doesn’t have a draft and that you can clean up easily. mess, so be sure and work somewhere that doesn’t have a draft and that you can clean up easily.

According to the reader who submitted this method, the monofilament and clear wrap are easy to separate out after the “rough cut” or during sifting.

Once you have a pile of pre-processed straw bits, you’ll want to sift it to get the dust out. The reader who sent these jig photos uses a flour sifter. While you’re sifting, you can easily pick out the clear wrap and monofilament that you sawed through to create your batch. Next stop: Chopping, or, as many readers call it affectionately, the “blender dance.”

Pre-Dyed Straws

Another reader has experimented with straw that has been pre-ironed and pre-dyed for use in various crafts.

Preprocessing May Not Be Necessary: This reader has made small batches by punching the straws with a very small paper punch that makes rectangles. If you want to try this way, you may not have to preprocess, dye or dry.

The photo below left shows the paper punch that makes the little rectangles plus some of the punched coconut bits. The reader who sent this photo also whacked the punched-out pieces with a knife several times to make them a little smaller and less regular in shape. Then the material did a brief stint in a spice grinder, although the contributor admits that might have been overkill. The photo below right shows a small container of punched, whacked, and ground coconut, probably enough for a small house.

Preprocessing: If you are going to be chopping this with a blender or some such, you’ll need cut it into 1” or smaller pieces before you chop it. Very sharp scissors will do it.

Corn Silk

One reader has experimented with corn silk. If you can harvest it while the ears are still on the stalk, you’ll get the lightest color (bleaching corn silk dissolves it, so that’s not an option).

Preprocessing: Very little preprocessing is needed - mostly you need to let it dry thoroughly. If it’s dry enough, the sifting process will break it up into the right size for houses.

Craft Products Using Rice Straw

At least one reader has attempted to use inexpensive craft products that were made with rice straw. These included placemats, etc. that turn up at the thrift shop.

Preprocessing: Will include separating it from the product and cutting into lengths of 1” or less.

Conclusion

If you’re looking for one good proven method that will work for everybody, this may not be what you were looking for. But so far there’s not single “best practice” that works for everybody, regardless of their skills, interests, and resources.

In other words “Do try this at home.” And when you do, feel free to report your results on the Coconut page of our forums.

In the meantime, I look forward to hearing and seeing the results of your experiments, with this or any other aspects of putz collecting, displaying, restoring, or creating.

Paul Race

CardboardChristmas.com

|